Manufacturing method of potassium carbonate

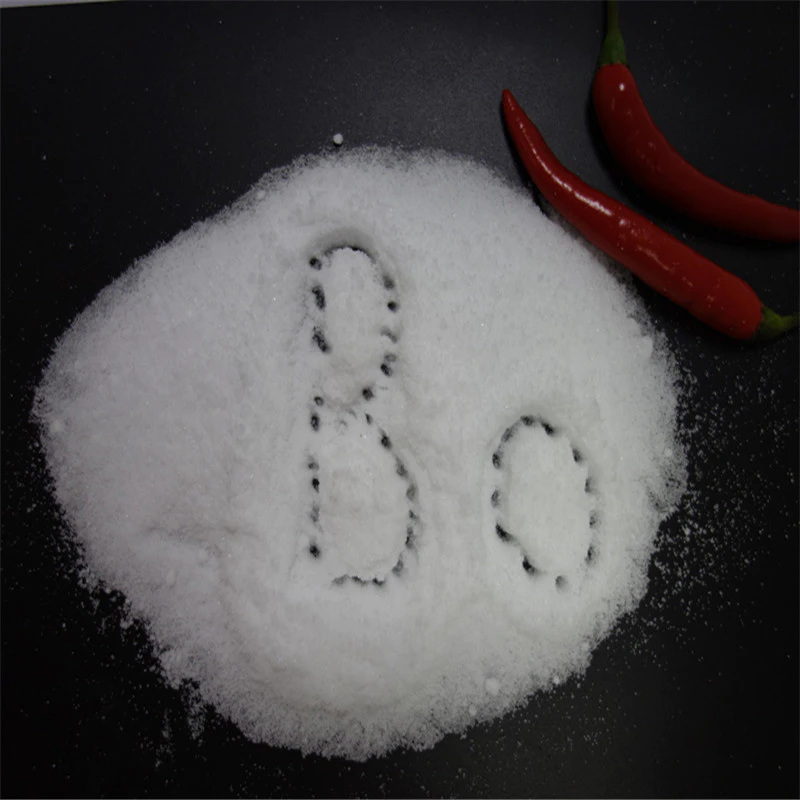

potash, also known as potash, pearl ash, crude potassium carbonate, white powder or granule, soluble in water, insoluble in ethanol and ether. The current has light and heavy industrial products. Potash producer has a lot of, zhejiang ocean and shanxi, the main production of lightweight potash, and hebei xinji, qinghai salt lake, as well as jiangsu high interest, the main production of heavy potash.

potassium carbonate is mainly used in chemical, pharmaceutical and other industries, is also used in food industry and agriculture, in manufacturing glass, soap, and other products, the potash has played a very important role.

about potassium carbonate manufacturing method, at present there are four, plant ash, lu LAN, electrolysis, ion exchange method, and the commonly used method is the electrolytic process and ion exchange method.

the electrolytic process, is will get potassium hydroxide potassium chloride electrolytic solution, carbide in the carbonization tower, filter get potassium bicarbonate, after calcination of potash. This method of reactants, high potassium utilization, and environmental protection, so this method is widely used, but this method has more power consumption.

the so-called ion exchange method, is with cation exchange resin with potassium chloride, again by ammonium bicarbonate elution into potassium bicarbonate solution, finally after evaporation, carbonation, crystallization, separation and calcination process. This method is of high product quality and manufacturing process is shorter, but the price is higher, therefore, this method is suitable for small-scale production.