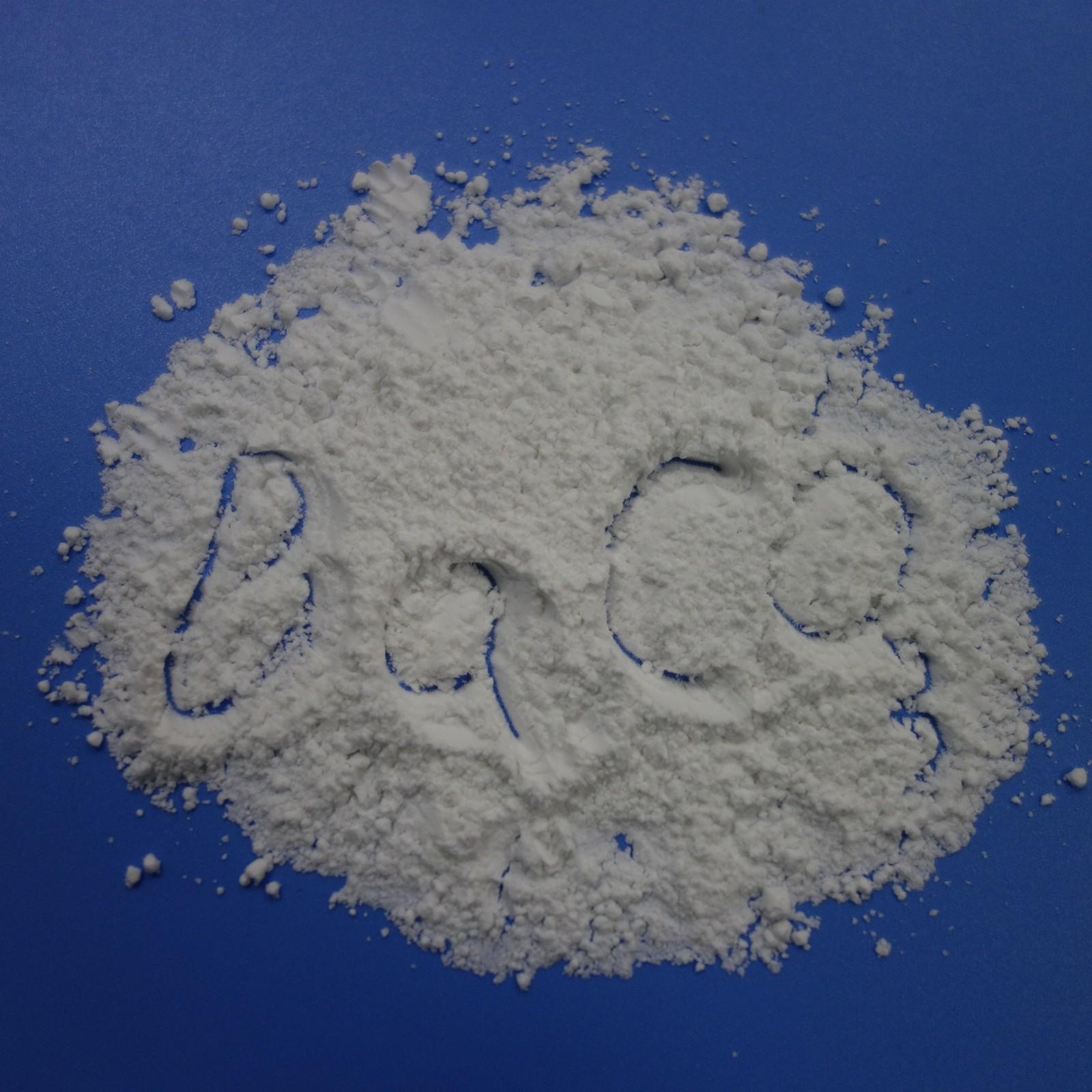

Barium carbonate (BaCO3), also known as witherite, is a chemical compound used in rat poison, bricks, ceramic glazes and cement.

The mineral is named after William Withering, who in 1784 recognized it to be chemically distinct from barytes. It occurs in veins of lead ore at Hexham in Northumberland, Alston in Cumbria, Anglezarke, near Chorley in Lancashire and a few other localities. Witherite is readily altered to barium sulfate by the action of water containing calcium sulfate in solution and crystals are therefore frequently encrusted with barytes. It is the chief source of barium salts and is mined in considerable amounts in Northumberland. It is used for the preparation of rat poison, in the manufacture of glass and porcelain, and formerly for refining sugar.It is also used for controlling the chromate to sulfate ratio in chromium electroplating baths.

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved